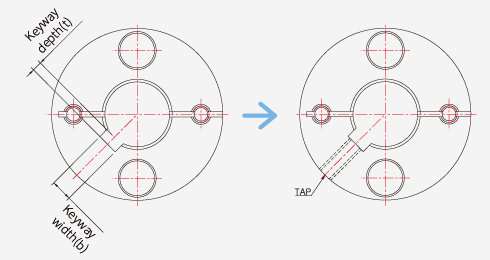

Keyway on Coupling Hubs

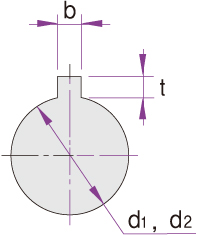

| Shaft(Bore) Diameter | Keyway Dimension | Nominal Size | |||||

|---|---|---|---|---|---|---|---|

| Ød1/ Ød2 | b(mm) | t(mm) | (b x h) | ||||

| Over ~ To | Mark | No Mark | H | J | Size | Tolerance | |

| Size | Tolerance(E9) | Tolerance(H9) | Tolerance(Js9) | ||||

| Ø6(over) ~ Ø8 | 2 | +0.039 +0.014 |

+0.025 0 |

±0.0125 | 1 | +0.1 0 |

2 x 2 |

| Ø8 ~ Ø10 | 3 | 1.4 | 3 x 3 | ||||

| Ø10 ~ Ø12 | 4 | +0.05 +0.02 |

+0.03 0 |

±0.015 | 1.8 | 4 x 4 | |

| Ø12 ~ Ø17 | 5 | 2.3 | 5 x 5 | ||||

| Ø17 ~ Ø22 | 6 | 2.8 | 6 x 6 | ||||

| Ø22 ~ Ø30 | 8 | +0.061 +0.025 |

+0.036 0 |

±0.018 | 3.3 | 8 x 7 | |

| Ø30 ~ Ø38 | 10 | +0.2 0 |

10 x 8 | ||||

| Ø38 ~ Ø44 | 12 | +0.075 +0.032 |

+0.043 0 |

±0.0215 | 12 x 8 | ||

| Ø44 ~ Ø50 | 14 | 3.8 | 14 x 9 | ||||

| Ø50 ~ Ø58 | 16 | 4.3 | 16 x 10 | ||||

| Ø58 ~ Ø65 | 18 | 4.4 | 18 x 11 | ||||

| Ø65 ~ Ø75 | 20 | +0.092 +0.04 |

+0.052 0 |

±0.026 | 4.9 | 20 x 12 | |

| Ø75 ~ Ø85 | 22 | 5.4 | 22 x 14 | ||||

- The location of keyway on a coupling hub is determined by the standard product design of Sung-il Machinery. If you need a keyway in a different location, please discuss with our Customer Support team in advance.

- The standard keyway tolerance is E9, which is the most suitable option in terms of the assembly convenience.

- If a specific keyway tolerance is required for a special case, please choose the code from the table and mention it on the PO. (Please refer to “How to order” below)

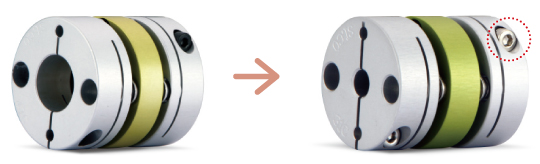

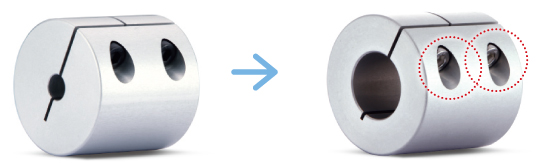

- Keyways can be applied on the following clamping methods of couplings. ※ exception 1: SFC series – Structurally impossible to have keyway

※ exception 2: SAD series - Due to structural interference (increased number of assembly holes),

we ask you to check with our customer support team for availability in advance.

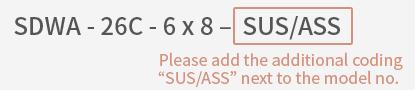

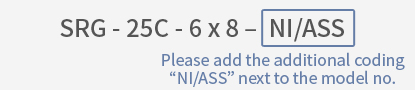

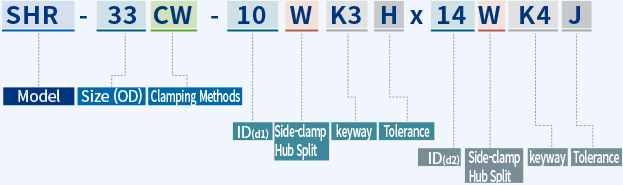

※ HOW TO ORDER

- Please indicate K(b=width) next to ID(d1)

- In general, t(depth) of a keyway is automatically determined by b(width). However if a keyway with special dimension is required, please discuss with our Customer Support team in advance. (For example, K3 will be provided with b(3mm) & t(1.4mm) unless there is a special remark.)

- Keyway Tolerance

Mark No Mark H J Tolerance E9 H9 Js9