Product

Support Unit

For Ball screw

Korean made support unit, ball screw components, support unit varieties, support unit endblock, support block, support end block, end block for ball screw, ball screw end blocks , support block for ball screw, ball screw accessories, ISO 9001, ISO 14001, Korean made components, IT components, mechanical components, motion components, motion accessories, motion control, motion control components, semi conductor components, display machine components, small sized machine components, small mechanical components, machine components, factory automation part

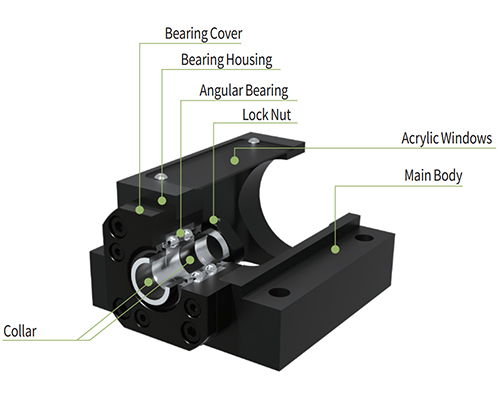

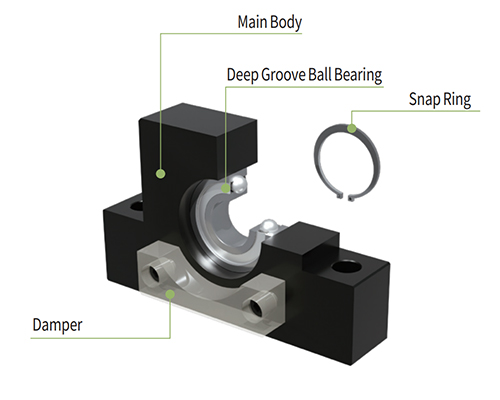

Support unit for ball screw helps to support each shaft-ends of

ball screw. We, S.I.M provides diverse options according to sizes,

loads and purposes for our customers’ best convenience.