Shaft Coupling

Coupling is a core component that transmits power and motion

from the driving shaft to the driven part while absorbing misalignment

and any possible factors that could reduce efficiency of machines

(e.g. vibration, noise, electric current, etc.)

Coupling Installation Guide

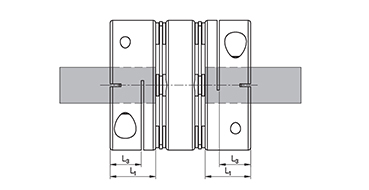

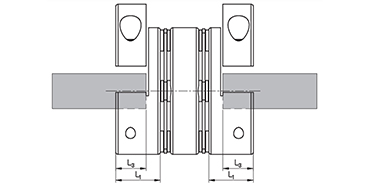

Suggested Shaft-insertion Depth

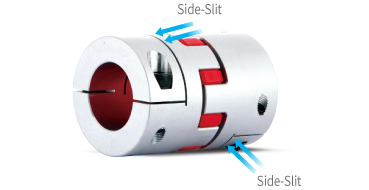

Side-clamp

Side-clamp Split

- The most ideal length of shaft-insertion is up to ‘L1’ on each dimension pages. (For side-clamp split type, it is up to ‘L3’.)

- If a shaft is not inserted deep enough into the coupling, it could make the shaft slipped out or make the coupling hub broken.

- If a shaft is inserted into the coupling too deeply, the coupling could be broken easily due to the interference between the shaft and coupling’s inner part or interference between both shafts.

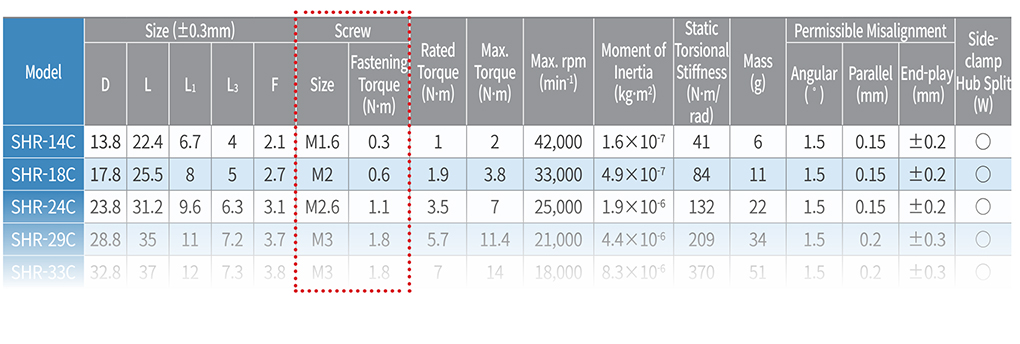

Precautions for Screw tightening

After inserting the shaft, when tightening the coupling screws, be sure to refer to the fastening torque values in the product specification table and tighten accordingly.

- If the fastening torque of the screw is low, the clamping force of the coupling may not be sufficiently exerted and slip may occur.

- If the fastening torque of the screw is excessive, the bottom of the screw head may sink, depending on the material of the internal thread (coupling). This could lead to a loss of tension in the fastening screws and a decrease in clamping force.

- Moreover, exceeding the yield point can cause a rapid increase in elongation rate, resulting in permanent deformation of the screw, and in severe cases, it may lead to breakage.

- Always tighten the fastening bolts after inserting the shaft. Fastening the screw without inserting the shaft can cause deformation of the coupling hub.

Fastening D-cut shaped shaft into a Coupling (Only Side-clamp Type)

Technically, the adequate clamping force can be guaranteed only with round-shaped shaft. However, in case D-cut shaped shaft has to be used, please follow the below instructions.

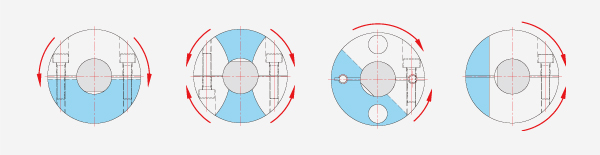

Case 1 : With side-slits

As shown in the below example, in a side-slit coupling structure there are normally 2 parts, side-slit (white area) and the rest (blue area). The mechanism of contraction differs by the location of side-slit and shape of each couplings. If a D-cut shaped shaft is inserted into a coupling, it should be located in the blue area, which is not affected by contraction when fastening screws. Please be aware that the clamping force may become lower under an inappropriate shaft fastening.

Examples of D-cut shaped shaft-insertion

Case 2 : Without side-slits

There is no side-slits on space-saving side-clamp couplings e.g. SJCM, SOHM etc. In this case, the D-cut shaft should be located right opposite to contraction (screw-fastening) side.

Examples of D-cut shaped shaft-insertion