Timing Pulley

Timing pulley is a part that transmits the rotational power

received from the timing belt to the shaft. Our products provide

sufficient tightening force without additional processing on shafts / pulleys, etc.

and support a variety of shaft fastening methods that are easy to install.

Installation Guide

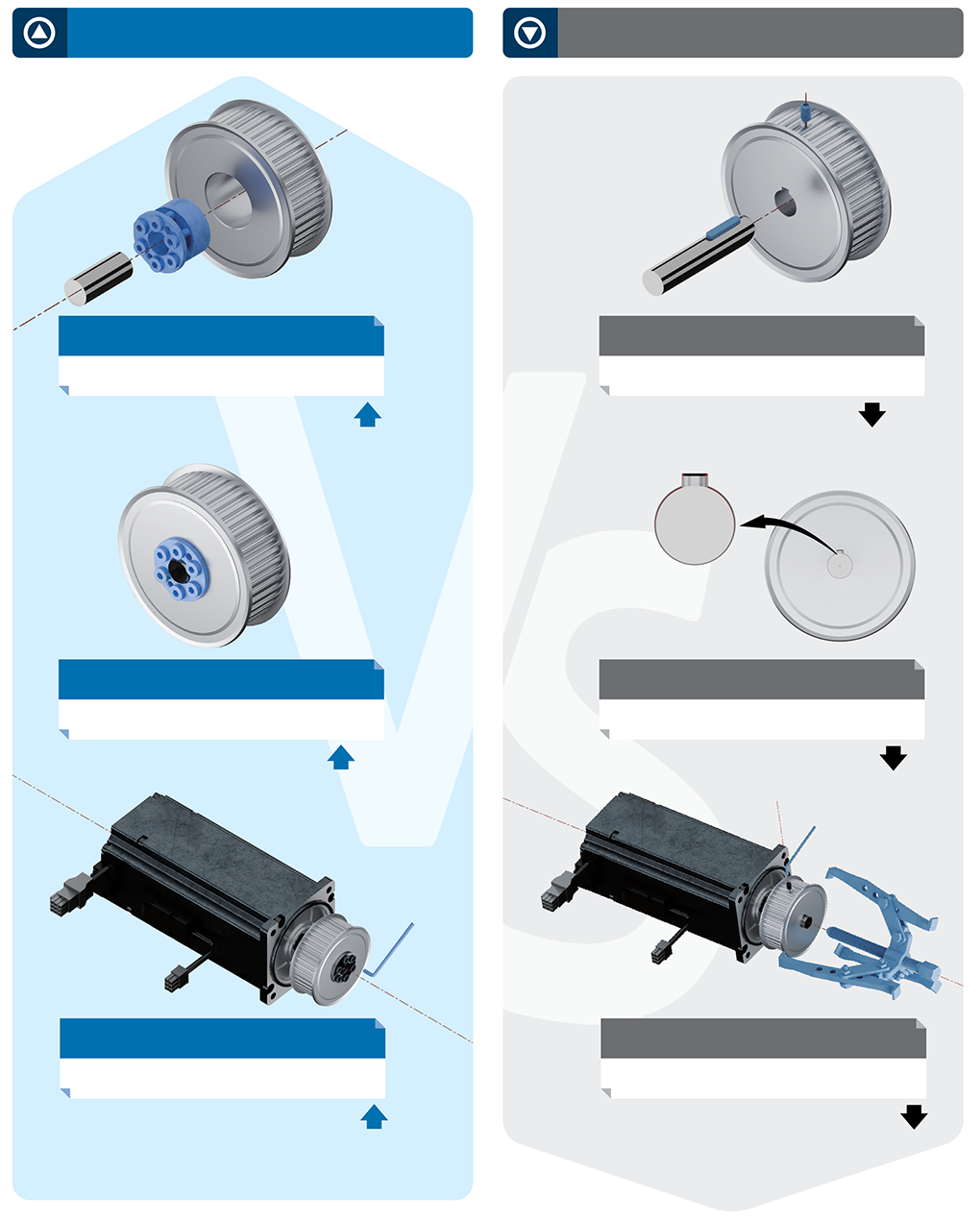

Comparison of Common Clamping Methods

SURFACE-CONTACT KEYLESS VERSION

No Additional Machining Required

Flexible for Emergency Deliveries

HIGH EFFICIENCY

No Additional Machining Required

Unlimited Position Adjustments

HIGH DURABILITY

Removal Tool:Standard Wrenches Sufficient

Reusable and Sustainable Solution

EASY MAINTENANCE

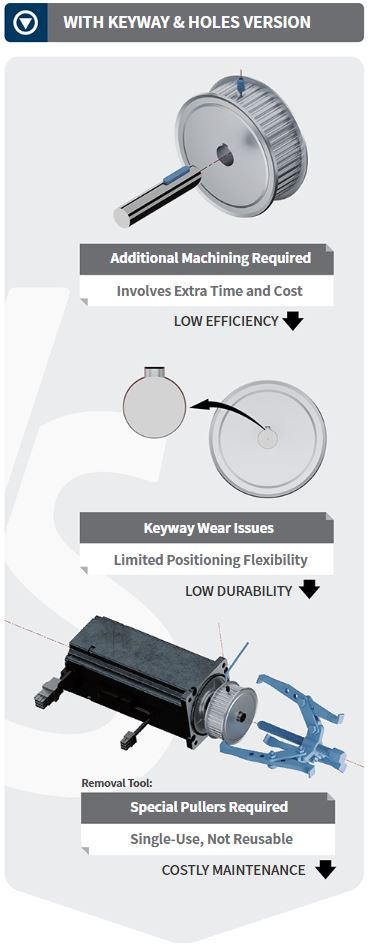

WITH KEYWAY & HOLES VERSION

Additional Machining Required

Involves Extra Time and Cost

LOW EFFICIENCY

Keyway Wear Issues

Limited Positioning Flexibility

LOW DURABILITY

Removal Tool:Special Pullers Required

Single-Use, Not Reusable

COSTLY MAINTENANCE

HOW TO INSTALL (SPA□, SPB)

- 1. Wipe inner surface of shaft and hub to remove dust and oil.

- 2. Wipe inner and outer surface of A.P.Lock or Taper Bushing.

- 3. Spread anti-wear hydraulic oil or grease on to all inner surfaces.

- 3.1 A.P. Lock which is made of aluminum alloy does not require any anti-wear hydraulic oil.

- 3.2 Any oil type which includes molybdenumsulfur compounds or silicone is prohibited.

- 4. Interlock A.P.Lock/Taper bushing with Timing Pulley and shaft respectively.

- (Do not fasten screws when the shaft is not inserted due to deformation.)

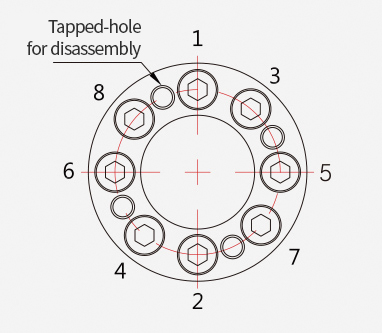

- 5. After positioning, fasten the screws as stated following.

- 5.1 Fasten the screws with identical torque (1/8 of fastening torque) using torque wrench.

- 5.2 Make sure you fasten the screws in sequential order as shown on the right figure.

- 5.3 Repeat fastening the screws with 1/4 of fastening torque. (in diagonal order)

- 5.4 Repeat fastening the screws with 1/2 of fastening torque. (in diagonal order)

- 5.5 Finally fasten the screws with full fastening torque.

- 5.6 Repeat fastening until screws don’t rotate any longer.

HOW TO DISASSEMBLE (SPA□, SPB)

- 1. Remove external load (torque/thrust) on the shaft and Timing Pulley.

- 2. Remove self-load of belt etc.

- 3. Unfasten all screws in the same order when they were fastened.

- 4. In case A.P. Lock or Taper bushing is not detached properly, try to disassemble using the tapped-hole for disassembly.