Structure and Material

| Structure | Material | Surface Treatment |

|---|---|---|

| Hub | Steel | Black Oxide |

| Plate Spring | Stainless Steel | - |

| Spacer(Collar) | Steel | Black Oxide |

| Assembly Screw | SCM435 | Black Oxide |

| Fastening Screw | SCM435 | Black Oxide |

Product Features & Application

| Backlash free (Precision) | ☆ |

|---|---|

| High Torque (Durability) | ☆ |

| Torsional Stiffness | ☆ |

| Vibration Absorption | - |

| Misalignment Absorption | △ |

Application : Machine tools, Chip mounters, Cartesian Robot, Solar energy equipment

How to Install

- 1. Remove dust or oil substances from the surface of both the coupling and the shaft.

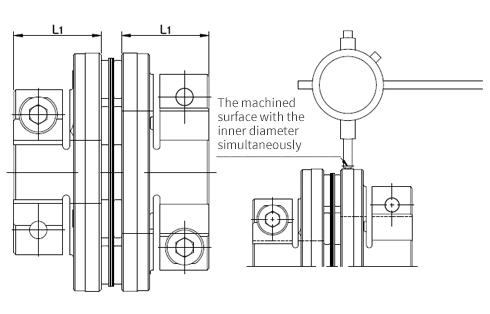

- 2. Insert the shaft up to L1. Make sure the plate spring doesn’t get pressed by excessive force.

- 3. After the shaft is inserted, pre-tighten two fastening screws alternately with limited torque, in order not to make it too loose.

- 4. Place a dial gauge right on the surface which is machined with the inner diameter simultaneously (see figure), and fasten the screws alternately observing the gauge variation (run-out) is less than 0.02.

- 5. Lastly, fasten the screws with full of fastening torque by using a torque wrench.

- 6. Insert the opposite shaft while paying attention to the excessive force on the plate spring and fasten screws according to the above instruction.

※ We recommend you only use the provided screws which are lubricated.

Clamping Methods

| Set-screw (No mark) | General | X |

|---|---|---|

| With Keyway | X | |

| Side-clamp (C) | General | ○ |

| Hub Split | X | |

| With Keyway | X | |

| Taper-ring (T) | X | |

How to Order

※ To verify the precise appearance of the product, please refer to the standard product drawing files provided on the top of our website's specification table or in the technical data section.