Shaft Coupling

Coupling is a core component that transmits power and motion

from the driving shaft to the driven part while absorbing misalignment

and any possible factors that could reduce efficiency of machines

(e.g. vibration, noise, electric current, etc.)

SCD Series

Concentricity Disk Coupling

| Single Disk | Double Disk | |

|---|---|---|

| Model | SCDS-C | SCDW-C |

| Shape |  |

|

| Hub Material | Steel | |

| Clamping Methods | Side-clamp | |

| OD range | Ø68-Ø88 | |

| ID range | Ø18-Ø42 | |

| For more info | View more > | View more > |

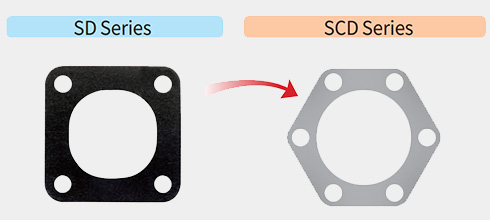

SCD vs SD

SCD Series is an advanced version of the general Disk type Coupling (SD series), with its plate-spring structure and the hub shape modified to make the coupling more durable and stiff. This enhancement allows for more precise installation of the coupling and enables faster rotation.

Advanced version of Plate Spring shape

The advanced plate spring with 6 assembly holes and these holes have narrower distance than 4-hole structure (SD series). Thus, SCD series is less flexible than SD series. On the other hand, increasing the number of assembly holes helps to disperse stress and it makes its module more durable and stiff. This advanced disk coupling is suitable for the purpose of enhanced performance, being able to replace similar sized disk couplings.

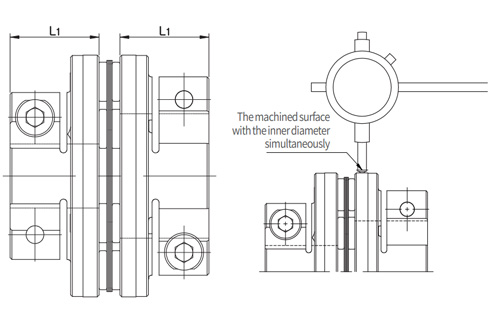

How to Install

※ We recommend you only use the provided screws which are lubricated.

- Remove dust or oil substances from the surface of both the coupling and the shaft.

- Insert the shaft up to L1. Make sure the plate spring doesn’t get pressed by excessive force.

- After the shaft is inserted, pre-tighten two fastening screws alternately with limited torque, in order not to make it too loose.

- Place a dial gauge right on the surface which is machined with the inner diameter simultaneously (see figure), and fasten the screws alternately observing the gauge variation (run-out) is less than 0.02.

- Lastly, fasten the screws with full of fastening torque by using a torque wrench.

- Insert the opposite shaft while paying attention to the excessive force on the plate spring and fasten screws according to the above instruction.