Shaft Coupling

Coupling is a core component that transmits power and motion

from the driving shaft to the driven part while absorbing misalignment

and any possible factors that could reduce efficiency of machines

(e.g. vibration, noise, electric current, etc.)

SCD Series Go to SCD Series(Index)

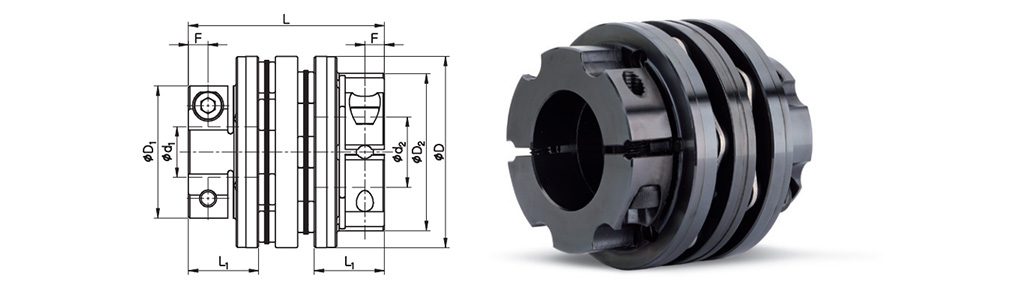

Concentricity Disk Type Coupling [SCDW]

Side-clamp

Dimensions / Performance

- The Moment of Inertia and Mass values are based on products with max.Inner diameter.

- The permissible torque is determined by its inner diameter size. Please refer to the bottom of the page for more details.

Standard Inner Diameter (ID)

| Model | Permissible Torque (N·m) |

Standard Inner Diameter (d1, d2) (mm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 18 | 19 | 20 | 22 | 24 | 25 | 26 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | ||

| SCDW-68C | 90 | ● | ● | ||||||||||||

| 100 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| SCDW-78C | 200 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| SCDW-88C | 250 | ● | ● | ● | |||||||||||

| 300 | ● | ● | ● | ● | ● | ● | |||||||||

- The recommended shaft tolerance is h7.

- Custom process (e.g.non-standard Inner diameter, special tolerance etc.)is also available upon a special request in prior to order placement.

- The permissible torque of a complete SCD coupling should be considered according to the smaller inner diameter’s value.

- Keyway is NOT available for all sized SCD series.