Shaft Coupling

Coupling is a core component that transmits power and motion

from the driving shaft to the driven part while absorbing misalignment

and any possible factors that could reduce efficiency of machines

(e.g. vibration, noise, electric current, etc.)

SHD Series Go to SHD Series(Index)

Double Disk High Torque Disk Coupling

- Product Overview

-

Dimensions / Performance / CAD

Structure & Material (Size : 50 ~ 110)

| Structure | Material | Surface Treatment |

|---|---|---|

| Hub | AL-7075-T6 | Anodizing |

| Middle Hub | AL-7075-T6 | |

| Plate Spring | Stainless Steel | – |

| Spacer(Collar) | Steel | Black Oxide |

| Assembly Screw | SCM435 | Black Oxide |

| Fastening Screw | SCM435 | Black Oxide |

Structure & Material (Size : 126 ~ 144)

| Structure | Material | Surface Treatment |

|---|---|---|

| Hub | Steel | Black Oxide (Standard) |

| Middle Hub | Steel | |

| Plate Spring | Stainless Steel | – |

| Spacer(Collar) | Steel | Black Oxide |

| Assembly Screw | SCM435 | Black Oxide |

| Fastening Screw | SCM435 | Black Oxide |

※ Please contact Sung-il Customer Service team for eletroless nickel plating surface treatment option.

Product Features & Application

| Backlash free (Precision) | ☆ | |

|---|---|---|

| High Torque (Durability) | ☆ | |

| Torsional Stiffness | ☆ | |

| Vibration Absorption | – | |

| Misalignment Absorption | ○ | |

| Applicable Motors | Servo | ○ |

| Stepping | ○ | |

| Encoder | – | |

| General | ○ | |

Application : Cartesian Robot, Belt Drive, Machine tools, Index Table, Logistics facilities, Servo Press etc.

Parts with Alternative Material Options

Sung-il Machinery provides alternative material options for Coupling parts for customers who are worried about corrosion on Black oxide finish. Please see the below table for more details.

| Mark | Material | Surface Treatment |

|---|---|---|

| No mark | Steel | Black Oxide |

| SUS/ASS | Stainless Steel | – |

Caution : Slip torque would become lower if the body material or surface treatment of screws are changed from the standard version.

Clamping Methods

| Set-screw (No mark) |

General | △ |

|---|---|---|

| With Keyway | △ | |

| Side-clamp (C) | General | ○ |

| Hub Split | ○ | |

| With Keyway | ○ | |

| Taper-ring (T) | △ | |

※ You may check the sizes that Side-clamp Hub Split type is applicable from the “Dimensions / Performance” tables in the following pages.

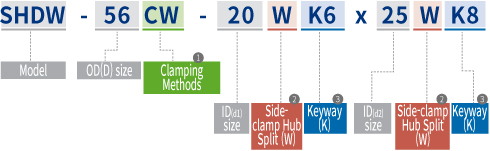

How to Order

① Clamping Methods

- No mark

- Set-screw

- C

- General Side-clamp

- CW

- Side-clamp Hub Split

- T

- Taper-ring

② Side-clamp Hub Split

- No mark

- Not Split

- W

- Split (Only applicable on Side-clamp Type)

③ Keyway

- No mark

- No Keyway

- K(b size)

- Keyway processed according to the indicated b size.

(Keyway is not applicable on Taper-ring type)

※ To verify the precise appearance of the product, please refer to the standard product drawing files provided on the top of our website’s specification table or in the technical data section.

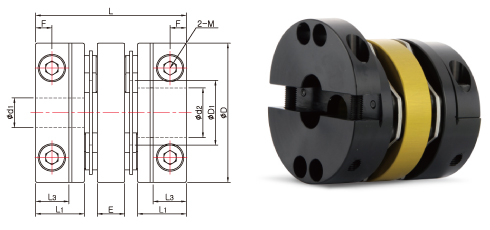

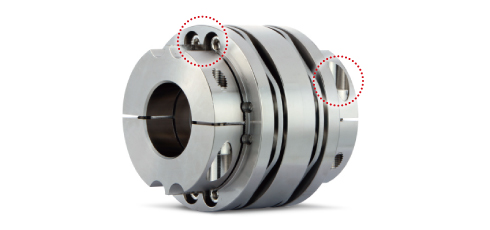

Side-clamp Hub Split(W) Option is available

- From certain outer diameter (OD) sizes, we can provide Side-clamp Hub Split products. Please refer to “HOW TO ORDER” page for more details.

- The no. of fastening screws for OD 50~110 products is only 1 each, however we provide 2 screws for Side-clamp Split (W) type according to the below drawing.

Electroless Nickel Plating for Steel-body Products

- The standard surface treatment (finish) for steel-body product is Black Oxide.

- If corrosion is highly concerned, there is another surface treatment option of ‘Electroless Nickel Plating’ adding an additional code “NI” next to the part no. as shown below.

SHDW-126C-NI-30-40

- All other parts (collars, ASS screws and FAS screws) will be Electroless Nickel Plated as well.

Caution : Slip torque would become lower if the body material or surface treatment of screws are changed from the standard version.