Shaft Coupling

Coupling is a core component that transmits power and motion

from the driving shaft to the driven part while absorbing misalignment

and any possible factors that could reduce efficiency of machines

(e.g. vibration, noise, electric current, etc.)

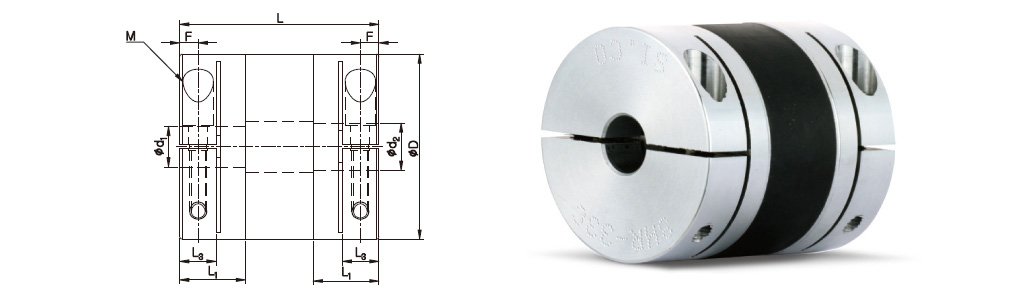

SHR Series

High Performance Rubber Coupling

Side-clamp

Dimensions / Performance

- The Moment of Inertia and Mass values are based on products with max. Inner diameter.

- Please modify Permissible Torque value with temperature correction factor when it’s higher than 30°C.

- Permissible Torque is the value regarding to a coupling’s self-durability and is not related to slip-torque between the coupling bore and the shaft.

Standard Inner Diameter (ID)

| Model | Standard Inner Diameter (d1, d2) (mm) | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 4 | 4.5 | 5 | 6 | 6.35 | 7 | 8 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | |

| SHR-14C | ● | ● | ● | ● | ● | |||||||||||||||||||||

| SHR-18C | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||

| SHR-24C | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||

| SHR-27C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SHR-29C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SHR-33C | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||

| SHR-38C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| SHR-43C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| SHR-55C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| SHR-68C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

- The recommended shaft tolerance is h7.

- Custom process (e.g. non-standard Inner diameter, special tolerance etc.) is also available upon a special request in prior to order placement.

- Keyway is available. (Optional)

- Side-clamp Hub Split is available. (Optional)

Slip Torque

- The below table shows the actual permissible torque values when the slip torque value is lower than the coupling’s permissible torque value.

- If the slip torque value is lower than the coupling’s permissible torque value, please check and compare between the slip torque in the below table and the operating torque value of the connected motor. It is safer to size up the coupling or use a key/keyway when the slip torque value is lower than the motor’s operating torque.

- The below slip torque values may be subject to change according to different testing conditions. (e.g. shaft tolerance, surface roughness, surface treatment or acceleration/deceleration of driving shafts). On the other hand, the values could be affected when a different kind of fastening screw is used (body material or surface treatment). Therefore, we recommend you test under the same conditions before mounting.

| Model | Permissible Torque (N·m) |

Slip Torque (N.m) by Inner Diameter (d1, d2) | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 4 | 4.5 | 5 | 6 | 6.35 | 7 | 8 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | ||

| SHR-14C | 1 | 0.5 | 0.6 | 0.6 | 0.7 | 0.8 | ||||||||||||||||||

| SHR-18C | 1.9 | 1.5 | 1.5 | 1.6 | 1.9 | 2 | ||||||||||||||||||

| SHR-24C | 3.5 | 2.5 | 3 | 3.3 | 3.5 | |||||||||||||||||||

| SHR-27C | 4 | 1.5 | 2.5 | 2.8 | 3 | 3.2 | ||||||||||||||||||

| SHR-29C | 5.7 | 3.5 | 3.8 | 4 | 5 | |||||||||||||||||||

| SHR-33C | 7 | 7 | ||||||||||||||||||||||

| SHR-38C | 12 | 6.5 | 9 | 10 | 12 | |||||||||||||||||||

| SHR-43C | 16 | 14 | 16 | |||||||||||||||||||||

| SHR-55C | 32 | |||||||||||||||||||||||

| SHR-68C | 65 | 54 | 57 | 65 | ||||||||||||||||||||