Shaft Coupling

Coupling is a core component that transmits power and motion

from the driving shaft to the driven part while absorbing misalignment

and any possible factors that could reduce efficiency of machines

(e.g. vibration, noise, electric current, etc.)

SOH Series Go to SOH Series(Index)

Oldham Coupling_Polyacetal(POM)/ General

- Product Overview

-

Dimensions / Performance / CAD

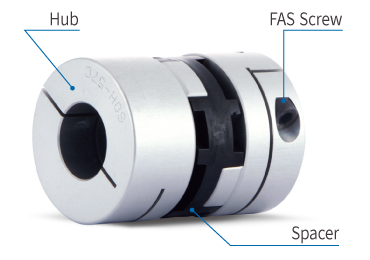

Structure & Material

| Structure | Material | Surface Treatment |

|---|---|---|

| Hub | High Strength Aluminum Alloy | Anodizing |

| Spacer | Polyacetal(POM) | – |

| Screw | SCM435 | Black Oxide |

- There is no surface treatment for SOH-6,8,10,12 (Set-screw) and SOHM-12C(Side-clamp).

Product Features & Application

| High Torque (Durability) | ○ | |

|---|---|---|

| Torsional Stiffness | △ | |

| Vibration Absorption | ○ | |

| Misalignment Absorption | ☆ | |

| Insulation of Electric Current | ○ | |

| Minimized Reaction Force | ☆ | |

| Oil Resistance | △ | |

| Applicable Motors | Servo | △ |

| Stepping | ○ | |

| Encoder | ○ | |

| General | ☆ | |

| Permissible Temperature | -20℃ ~ 80℃ | |

Application : Part feeder, Cartesian Robot, Logistics facilities

Temperature Correction Factor

Please modify rated/max. torque value with the below temperature correction factor when it’s higher than 30°C.

| Ambient Temperature | Correction Factor |

|---|---|

| -20 ℃ ~ 30 ℃ | 1.0 |

| 30 ℃ ~ 40 ℃ | 0.8 |

| 40 ℃ ~ 60 ℃ | 0.7 |

| 60 ℃ ~ 80 ℃ | 0.55 |

Clamping Methods

| Set-screw (No mark) |

General | △ |

|---|---|---|

| With Keyway | △ | |

| Side-clamp (C) | General | △ |

| Hub Split | △ | |

| With Keyway | △ | |

| Taper-ring (T) | X | |

※ You may check the sizes that Side-clamp Hub Split type is applicable from the “Dimensions / Performance” tables in the following pages.

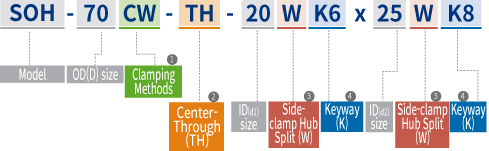

How to Order

① Clamping Methods

- No mark

- Set-screw

- C

- General Side-clamp

- CW

- Side-clamp Hub Split

② Center-Through

- No mark

- Center-Solid

- TH

- Center-Through

③ Side-clamp Hub Split

- No mark

- Not Split

- W

- Split (Only applicable on Side-clamp Type)

④ Keyway

- No mark

- No Keyway

- K(b size)

- Keyway processed according to the indicated b size.

※ To verify the precise appearance of the product, please refer to the standard product drawing files provided on the top of our website’s specification table or in the technical data section.