Support Unit For Ball screw

Support unit for ball screw helps to support each shaft-ends of

ball screw. We, S.I.M provides diverse options according to sizes,

loads and purposes for our customers’ best convenience.

Support Unit for Ball Screw (Index)

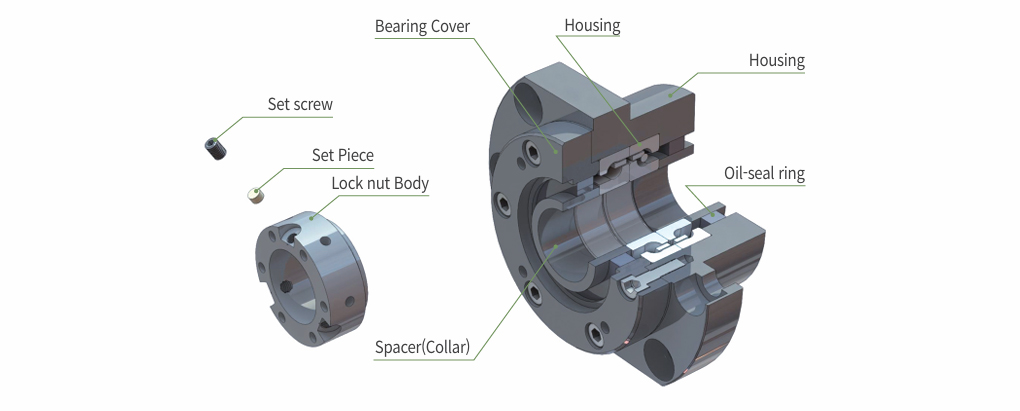

Support Unit (High load)

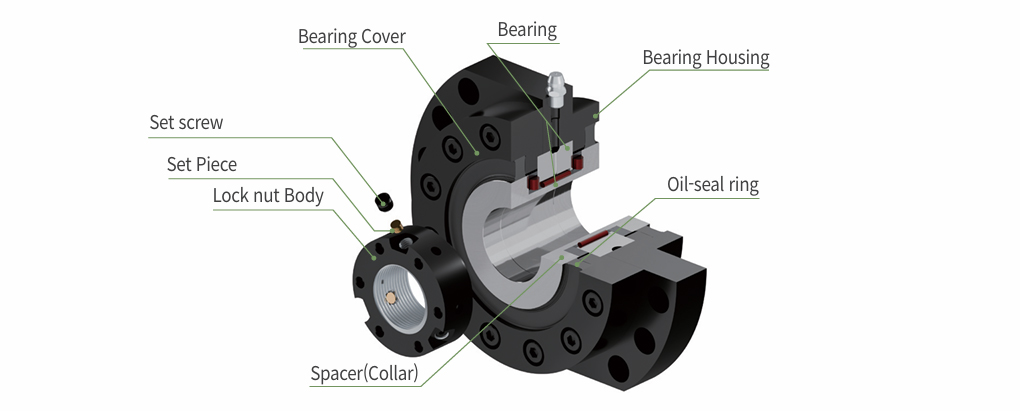

Structure

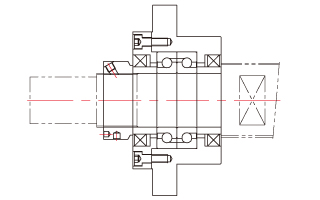

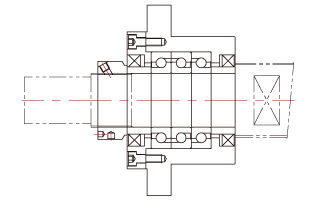

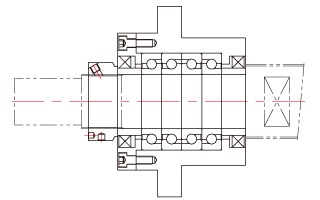

Bearing Combinations

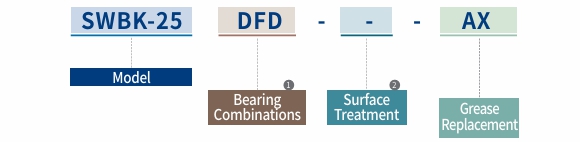

How to Order

| ① Bearing Combinations |

Mark | Combinations |

|---|---|---|

| DF | Double-row | |

| DFD | Triple-row | |

| DFF | Four-row |

| ② Surface Treatment |

Mark | Surface Treatment |

|---|---|---|

| No mark | Black Oxide | |

| RA | Low temperature Black Chrome Plating (Raydent) |

| Grease Model | Standard | LG2 | AFE-CA | AFF | HT-Z1 | NBU-15 | XL-600 |

|---|---|---|---|---|---|---|---|

| Mark | No mark | AG | AE | AF | AH | AN | AX |

※ For detailed information regarding grease replacement, please refer to the guideline pages in the catalogue under the “Made-To-Order Process.”

Features

- This product can accommodate higher loads compared to the SWBK series.

- Preload is determined by the fastening torque of the locknut; therefore, be sure to follow the recommended fastening torque.

- Supplied as standard with a grease injection type.

- The product comes with a locknut included.

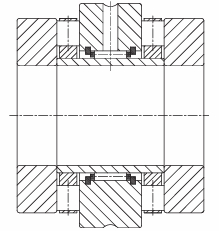

Structure

Bearing Combinations

- The wide contact surface of the cylindrical rollers supports both radial loads and partial axial loads, ensuring structural rigidity.

- The cage precisely keeps the rollers evenly spaced. This reduces friction, heat generation, and noise, enabling stable rotation even under high-load and high-torque conditions.

- The bearing is designed for direct grease injection, allowing long-term stable lubrication.

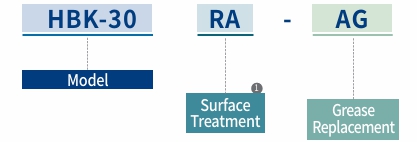

How to Order

| ① Surface Treatment |

Mark | Surface Treatment |

|---|---|---|

| No mark | Black Oxide | |

| RA | Low temperature Black Chrome Plating (Raydent) |

| Grease Model | Standard | LG2 | AFE-CA | AFF | HT-Z1 | NBU-15 | XL-600 |

|---|---|---|---|---|---|---|---|

| Mark | No mark | AG | AE | AF | AH | AN | AX |

※ For detailed information regarding grease replacement, please refer to the guideline pages in the catalogue under the “Made-To-Order Process.”

SWBK Series

| Model | Bearing Combinations |

Bearing | Basic Dynamic Load Rating (N) |

Limiting Static Axial Rating (N) |

Permissible Axial Load (N) |

Preload (N) |

Axial Rigidity (N/㎛) |

Starting Torque (N·cm) |

|---|---|---|---|---|---|---|---|---|

| SWBK-17 | DF | 17TAC 47C | 23,000 | 26,600 | 18,600 | 1,450 | 630 | 14 |

| SWBK-17 | DFD | 17TAC 47C | 37,500 | 53,000 | 37,100 | 1,970 | 930 | 19 |

| SWBK-20 | DF | 20TAC 47C | 23,000 | 26,600 | 18,600 | 1,450 | 630 | 14 |

| SWBK-20 | DFD | 20TAC 47C | 37,500 | 53,000 | 37,100 | 1,970 | 930 | 19 |

| SWBK-25 | DF | 25TAC 62C | 29,900 | 40,500 | 28,400 | 2,280 | 850 | 21 |

| SWBK-25 | DFD | 25TAC 62C | 48,500 | 81,500 | 57,100 | 3,100 | 1,250 | 28 |

| SWBK-30 | DF | 30TAC 62C | 30,500 | 43,000 | 30,100 | 2,400 | 890 | 23 |

| SWBK-30 | DFD | 30TAC 62C | 50,000 | 86,000 | 60,200 | 3,260 | 1,310 | 30 |

| SWBK-35 | DF | 35TAC 72C | 32,500 | 50,000 | 35,000 | 2,750 | 1,030 | 27 |

| SWBK-35 | DFD | 35TAC 72C | 53,000 | 100,000 | 70,000 | 3,740 | 1,500 | 34 |

| SWBK-35 | DFF | 35TAC 72C | 53,000 | 100,000 | 70,000 | 5,490 | 2,060 | 43 |

| SWBK-40 | DF | 40TAC 72C | 33,500 | 52,000 | 36,400 | 2,860 | 1,080 | 28 |

| SWBK-40 | DFD | 40TAC 72C | 54,000 | 104,000 | 72,800 | 3,900 | 1,590 | 36 |

| SWBK-40 | DFF | 40TAC 72C | 54,000 | 104,000 | 72,800 | 5,730 | 2,150 | 46 |

| SWBK-50 | DF | 50TAC 100C | 66,000 | 72,800 | 51,000 | 4,650 | 1,410 | 42 |

| SWBK-50 | DFD | 50TAC 100C | 107,000 | 145,600 | 101,900 | 6,320 | 2,100 | 57 |

| SWBK-50 | DFF | 50TAC 100C | 107,000 | 145,600 | 101,900 | 9,120 | 2,820 | 82 |

※The bearing brand may be subject to change with the same level products according to supplying conditions.

HBK Series

| Model | Basic Load(Axial) (N) |

Basic Load(Radial) (N) |

Axial Rigidity (N/㎛) |

Max. rpm (min-1) |

Max. Starting Torque (N·cm) |

||

|---|---|---|---|---|---|---|---|

| Dynamic | Static | Dynamic | Static | ||||

| HBK-30 | 90,400 | 216,200 | 18,100 | 32,900 | 3,100 | 1,300 | 140 |

| HBK-40 | 101,800 | 266,100 | 26,000 | 56,500 | 3,800 | 1,200 | 180 |

| HBK-50 | 163,000 | 453,000 | 35,600 | 64,400 | 5,300 | 1,100 | 360 |

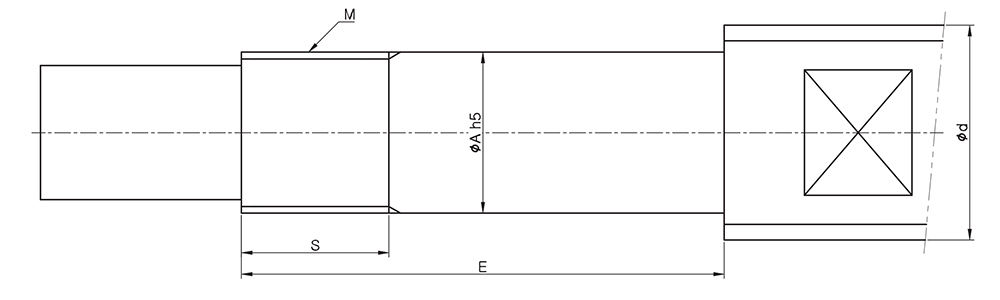

Recommended Shape Of Ball Screw Shaft-End (Fixed Side)

| Dimensions (mm) | Lock-nut | ||||||

|---|---|---|---|---|---|---|---|

| d | A | Model | E | S | Model | Size M x pitch |

|

| Ø25 – Ø28 | 17 | SWBK-17 | DF | 81 | 23 | HLRN-17 | M17 x 1.0 |

| DFD | 96 | ||||||

| 20 | SWBK-20 | DF | 81 | 23 | HLRN-20 | M20 x 1.0 | |

| DFD | 96 | ||||||

| Ø30 – Ø36 | 25 | SWBK-25 | DF | 89 | 26 | HLRN-25 | M25 x 1.5 |

| DFD | 104 | ||||||

| Ø40 | 30 | SWBK-30 | DF | 89 | 26 | HLRN-30 | M30 x 1.5 |

| DFD | 104 | ||||||

| HBK-30 | 89 | 26 | |||||

| Ø45 | 35 | SWBK-35 | DF | 90 | 28 | HLRN-35 | M35 x 1.5 |

| DFD | 105 | ||||||

| DFF | 120 | ||||||

| Ø50 – Ø55 | 40 | SWBK-40 | DF | 92 | 30 | HLRN-40 | M40 x 1.5 |

| DFD | 107 | ||||||

| DFF | 122 | ||||||

| HBK-40 | 101 | 30 | |||||

| Ø63 – Ø70 | 50 | SWBK-50 | DF | 117 | 34 | HLRN-50 | M50 x 1.5 |

| DFD | 137 | ||||||

| DFF | 157 | ||||||

| HBK-50 | 111 | 34 | |||||