Shaft Coupling

Coupling is a core component that transmits power and motion

from the driving shaft to the driven part while absorbing misalignment

and any possible factors that could reduce efficiency of machines

(e.g. vibration, noise, electric current, etc.)

SOH Series Go to SOH Series(Index)

Oldham Coupling_PEEK Spacer / For Vacuum application

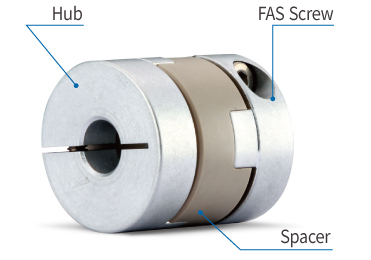

Structure & Material

| Structure | Material | Surface Treatment |

|---|---|---|

| Hub | High Strength Aluminum Alloy | – |

| Spacer | PEEK | – |

| Screw | STS304 | – |

Product Features & Application

| Minimized Outgas | ☆ |

|---|---|

| High Torque (Durability) | ○ |

| Torsional Stiffness | △ |

| Chemical Resistance | ○ |

| Misalignment Absorption | ☆ |

| Insulation of Electric Current | ☆ |

| Minimized Reaction Force | ☆ |

| Permissible Temperature | -20℃ ~ 120℃ |

Application : Semi-conductor machine, OLED vacuum machine, High-temperature applications, cleanroom facilities.

Features of SOHMP Series

- Excellent for Vacuum applications in regards of extremely low level of outgas. (In terms of outgas, SOHMP performs better than SOHSV Series)

- Suitable to be used in cleanroom facilities and high temperature applications.

Properties of PEEK Material

| Item | Test Method | Value | Unit | |

|---|---|---|---|---|

| Physical Properties |

Density | ISO 1183-1 | 1.31 | g/㎤ |

| Thermal Properties |

Heat Deflection Temperature (1.8 Mpa) |

ISO 75-1 | 160 | ℃ |

| Coefficient of Thermal Expansion (23 – 150℃) |

– | 55×10-6 | m/m·K | |

| Mechanical Properties |

Tensile Strength |

ISO 527-1 | 115 | Mpa |

| Elongation at yield |

ISO 527-1 | 5 | % | |

| Rockwell Hardness |

ISO 2039-2 | M105 |

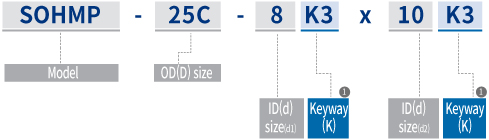

How to Order

① Keyway

- No mark

- No Keyway

- K(b size)

- Keyway processed according to the indicated b size.