Shaft Coupling

Coupling is a core component that transmits power and motion

from the driving shaft to the driven part while absorbing misalignment

and any possible factors that could reduce efficiency of machines

(e.g. vibration, noise, electric current, etc.)

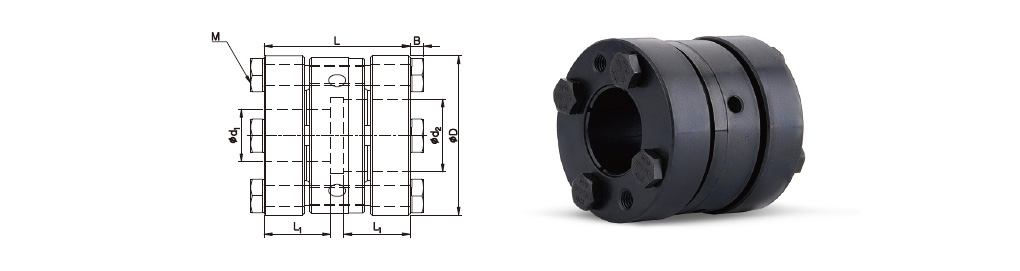

SRGP Series Go to SRG Series(Index)

Ultra High Stiffness Rigid Coupling (Steel Body)

Taper-ring

Dimensions / Performance

- The Moment of Inertia and Mass values are based on products with max. Inner diameter.

- The permissible torque is determined by its inner diameter size. Please refer to the bottom of the page for more details.

- Due to the structure of Taper-ring, it’s not allowed to have other complementary options (e.g. keyway etc.) to enhance clamping force.

Standard Inner Diameter (ID)

| Model | Standard Inner Diameter (d1, d2) (mm) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 18 | 19 | 20 | 22 | 24 | 25 | 25.4 | 28 | 30 | 32 | 35 | 40 | 42 | 45 | 48 | |

| SRGP-48T | ● | ● | ● | ● | ● | |||||||||||

| SRGP-54T | ● | ● | ● | ● | ● | ● | ||||||||||

| SRGP-64T | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| SRGP-78T | ● | ● | ● | ● | ● | ● | ● | |||||||||

- The recommended shaft tolerance is h7.

- Custom process (e.g. non-standard Inner diameter, special tolerance etc.) is also available upon a special request in prior to order placement.

Slip Torque

- The below table shows the actual permissible torque values when the slip torque value is lower than the coupling’s max. torque value.

- The below slip torque values may be subject to change according to different testing conditions. (e.g. shaft tolerance, surface roughness, surface treatment or acceleration/deceleration of driving shafts). On the other hand, the values could be affected when different kind of fastening screw is used. Therefore, we recommend you test under the same conditions before mounting.

- The permissible torque of a complete SRGP coupling should be considered according to the smaller inner diameter’s value.

| Model | Slip Torque (N.m) by Inner Diameter (d1, d2) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 18 | 19 | 20 | 22 | 24 | 25 | 25.4 | 28 | 30 | 32 | 35 | 40 | 42 | 45 | 48 | |

| SRGP-48T | 90 | 110 | 120 | 130 | 140 | |||||||||||

| SRGP-54T | 80 | 100 | 110 | 145 | 180 | 190 | ||||||||||

| SRGP-64T | 150 | 200 | 220 | 220 | 290 | 340 | 390 | 460 | ||||||||

| SRGP-78T | 180 | 220 | 240 | 360 | 390 | 440 | 490 | |||||||||