Timing Pulley

Timing pulley is a part that transmits the rotational power

received from the timing belt to the shaft. Our products provide

sufficient tightening force without additional processing on shafts / pulleys, etc.

and support a variety of shaft fastening methods that are easy to install.

SATP-8YU Series

Timing Pulley (High Strength Aluminum Alloy)  + A.P.LOCK (Steel) Mounted Type

+ A.P.LOCK (Steel) Mounted Type

Dimensions / Performance

• Please refer to the below table for more specific available ID(d) information.

|

Available ID (d) |

12 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

40 |

45 |

50 |

|

|

Max. Permissible Torque (N·m) |

I & O type |

50 |

65 |

70 |

75 |

110 |

115 |

120 |

220 |

290 |

320 |

350 |

380 |

410 |

440 |

720 |

810 |

1,200 |

1,500 |

|

Max. Permissible Thrust Load (kN) |

I & O type |

5.6 |

9.5 |

9.5 |

9.5 |

12.6 |

12.6 |

12.6 |

21.6 |

26 |

26 |

27.2 |

27 |

27 |

27 |

41.1 |

40.2 |

52.9 |

56.3 |

|

D |

I & O type |

28.5 |

30.5 |

31.5 |

33 |

33.5 |

34.5 |

35.5 |

42 |

44 |

46 |

47 |

50 |

52 |

54 |

62 |

67 |

72 |

77 |

|

N |

I & O type |

6.5 |

6.5 |

6.5 |

6.5 |

6.5 |

6.5 |

6.5 |

8 |

8 |

8 |

8 |

8.5 |

8.5 |

8.5 |

10 |

10 |

10 |

10.5 |

• Keyway is NOT available for SPAS series.

• Surface treatment may not be applied on inner surface of Pulley’s body.

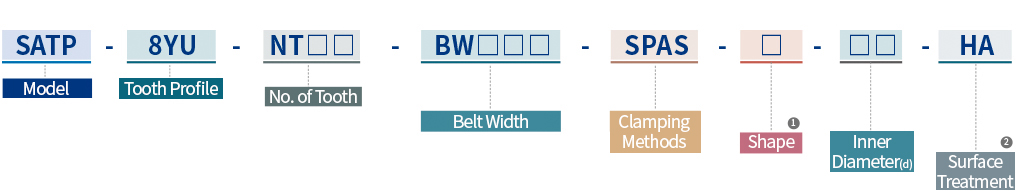

How to Order

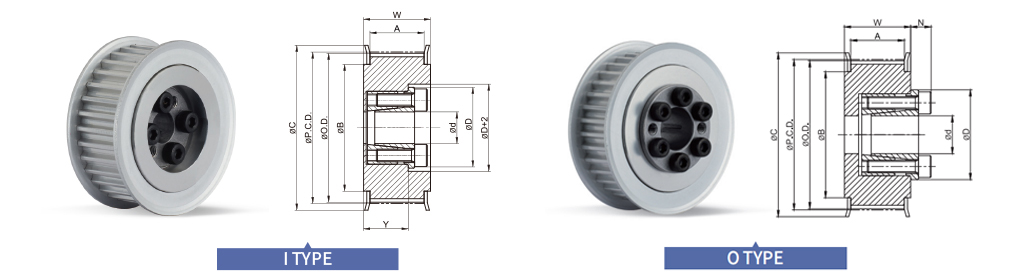

① Shape

- I

- Flange part of A.P.Lock and Taper bushing is located inside

- O

- Flange part of A.P.Lock and Taper bushing is located outside

② Surface Treatment

- HA

- Hard Anodizing

- WA

- White Anodizing