Timing Pulley

Timing pulley is a part that transmits the rotational power

received from the timing belt to the shaft. Our products provide

sufficient tightening force without additional processing on shafts / pulleys, etc.

and support a variety of shaft fastening methods that are easy to install.

SATP-S5M Series

High Strength Aluminum Alloy Timing Pulley  + Taper Bushing (Steel) Mounted Type

+ Taper Bushing (Steel) Mounted Type

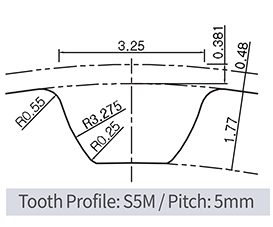

Dimensions / Performance

• Please refer to the below table for more specific available ID(d) information.

|

Available ID (d) |

8 |

10 |

11 |

12 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

|

|

Max. Permissible Torque (N·m) |

I type |

8.5 |

18 |

20 |

23 |

37 |

39 |

42 |

45 |

48 |

49 |

97 |

110 |

121 |

124 |

141 |

149 |

163 |

173 |

|

O type |

16 |

39 |

43 |

48 |

73 |

78 |

83 |

88 |

154 |

163 |

171 |

186 |

206 |

216 |

353 |

382 |

412 |

451 |

|

|

Max. Permissible Thrust Load (kN) |

I type |

2.12 |

3.59 |

3.63 |

3.76 |

5.21 |

5.1 |

5.17 |

5.23 |

5.28 |

5.12 |

9.68 |

9.98 |

10 |

9.9 |

10 |

9.89 |

10.12 |

9.88 |

|

O type |

5.34 |

5.34 |

5.34 |

5.34 |

5.34 |

5.34 |

5.34 |

5.34 |

8.74 |

8.74 |

8.74 |

8.74 |

8.74 |

8.74 |

8.74 |

8.74 |

8.74 |

8.74 |

|

|

D |

I type |

24.5 |

29 |

30 |

31 |

36 |

37 |

38 |

39 |

40 |

42 |

46 |

47 |

49 |

51 |

53 |

56 |

58 |

61 |

|

O type |

25.5 |

30 |

31 |

32 |

35 |

36 |

37 |

38 |

43 |

45 |

46 |

48 |

50 |

52 |

54 |

57 |

59 |

63 |

|

|

N |

O type |

8.5 |

10.5 |

10.5 |

10.5 |

12 |

12 |

13 |

13 |

14 |

14 |

14 |

14 |

14 |

14 |

15.5 |

15.5 |

16.5 |

16.5 |

• Keyway is NOT available for SPB series.

• Surface treatment may not be applied on inner surface of Pulley’s body.

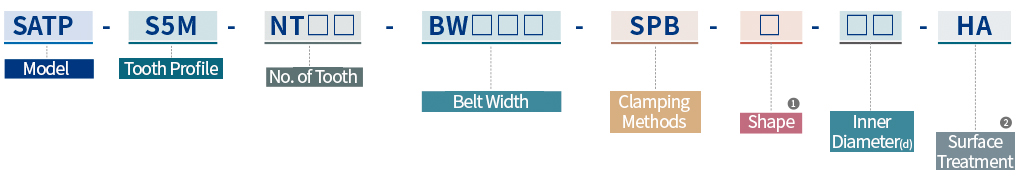

How to Order

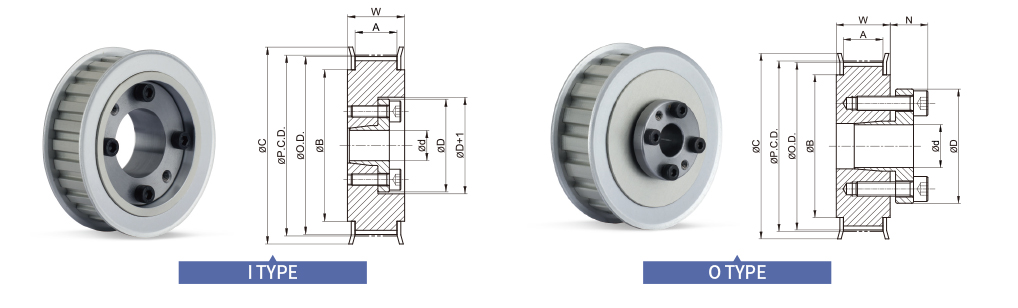

① Shape

- I

- Flange part of A.P.Lock and Taper bushing is located inside

- O

- Flange part of A.P.Lock and Taper bushing is located outside

② Surface Treatment

- HA

- Hard Anodizing

- WA

- White Anodizing