Shaft Coupling

Coupling is a core component that transmits power and motion

from the driving shaft to the driven part while absorbing misalignment

and any possible factors that could reduce efficiency of machines

(e.g. vibration, noise, electric current, etc.)

SJC Series

Jaw Coupling

- Product Overview

-

Dimensions / Performance / CAD

- Power transmission through the spider (sleeve) in the middle

- The highest durability comparing to other coupling series

- Various clamping methods available

- High precision with preloaded assembly

Set-screw|Size : 14 ~ 100 View more >

| Structure | Material | Surface Treatment |

|---|---|---|

| Hub | High Strength Aluminum Alloy | Anodizing |

| Sleeve | Hytrel®(RD/GR) TPU (DG/BL) |

– |

| Screw | SCM435 | Black Oxide |

Side-clamp (Space-saving)|Size : M-55C ~ M-100C View more >

| Structure | Material | Surface Treatment |

|---|---|---|

| Hub | High Strength Aluminum Alloy | Anodizing |

| Sleeve | Hytrel®(RD/GR) TPU (DG/BL) |

|

| Screw | SCM435 | Black Oxide |

Side-clamp|Size : 14C ~ 100C View more >

| Structure | Material | Surface Treatment |

|---|---|---|

| Hub | High Strength Aluminum Alloy | Anodizing |

| Sleeve | Hytrel®(RD/GR) TPU (DG/BL) |

– |

| Screw | SCM435 | Black Oxide |

Side-clamp|Size : 120C ~ 160C View more >

| Structure | Material | Surface Treatment |

|---|---|---|

| Hub | Steel | Electroless Nickel Plating |

| Sleeve | Hytrel®(RD/GR) | – |

| Screw | SCM435 | Electroless Nickel Plating |

Taper-ring|Size : 55T ~ 100T View more >

| Structure | Material | Surface Treatment |

|---|---|---|

| Hub | High Strength Aluminum Alloy | Anodizing |

| Sleeve | Hytrel®(RD/GR) TPU (DG/BL) |

– |

| Screw | SCM435 | Black Oxide |

Shaft-insertion|Size : 25I ~ 65I View more >

| Structure | Material | Surface Treatment |

|---|---|---|

| Hub | High Strength Aluminum Alloy | Anodizing |

| Sleeve | Hytrel®(RD/GR) TPU (DG/BL) |

– |

| Bushing | Stainless Steel | |

| Screw | SCM435 | Black Oxide |

Taper-ring type coupling (for high-precision / high-speed spindles)|Size : 55T ~ 100T View more >

| Structure | Material | Surface Treatment |

|---|---|---|

| Hub | Steel | – |

| Sleeve | Hytrel®(RD/GR) TPU (DG/BL) |

– |

| Screw | SCM435 | Black Oxide |

※ Taper-ring type coupling (for high-precision / high-speed spindles) is supplied as made-to-order. Hub and screw materials and surface treatments may vary depending on operating conditions.

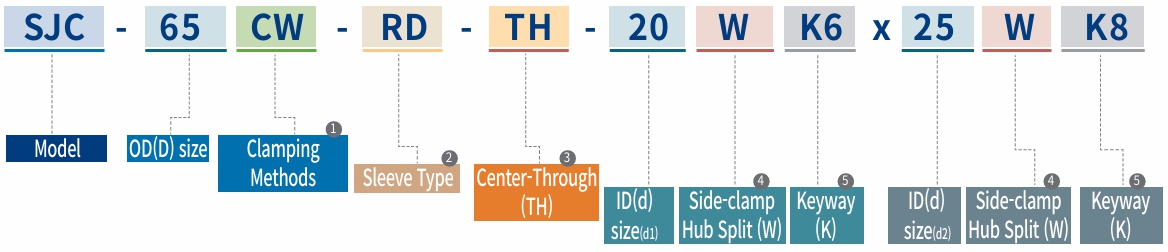

How to Order(Set-screw / Side-clamp / Taper-ring)

① Clamping Methods

- No mark

- Set-screw

- C

- General Side-clamp

- CW

- Side-clamp Hub Split

- T

- Taper-ring

② Sleeve Type (Shore Hardness)

- RD

- Hytrel, Sh63D

- GR

- Hytrel, Sh98A

- DG

- TPU, Sh57D

- BL

- TPU, Sh98A

③ Center-Through

- No mark

- Center-Solid

- TH

- Center-Through

④ Side-clamp Hub Split

- No mark

- Not Split

- W

- Split (Only applicable on Side-clamp Type)

⑤ Keyway

- No mark

- No Keyway

- K(b size)

- Keyway processed according to the indicated b size.

(Keyway is not applicable on Taper-ring type)

※ HOW TO ORDER(Shaft-insertion) : View more >

※ HOW TO ORDER (Taper-ring for high precision/spindle) : View more >

Side-clamp Hub Split(W) Option is available

- From certain outer diameter (OD) sizes, we can provide Side-clamp Hub Split products. Please refer to “HOW TO ORDER” page for more details.

Product Features & Application

| Sleeve Material | Hytrel (RD/GR) | TPU (DG/BL) | |

|---|---|---|---|

| Backlash free (Precision) | ○ | ○ | |

| High Torque (Durability) | ☆ | ☆ | |

| Torsional Stiffness | △ | △ | |

| Vibration Absorption | △ | ○ | |

| Misalignment Absorption | △ | △ | |

| Insulation of Electric Current | ○ | ○ | |

| Applicable Motors | Servo | ○ | ○ |

| Stepping | ○ | ○ | |

| Encoder | △ | △ | |

| General | ☆ | ☆ | |

| Permissible Temperature | -20℃ ~ 120℃ | -20℃ ~ 70℃ | |

Application : Machine tools, Press machine, Injection Molding machine, Pneumatic machine, Pump, Cartesian Robot, Belt Drive, Logistics facilities etc.

Clamping Methods

| Set-screw (No mark) |

General | △ |

|---|---|---|

| With Keyway | △ | |

| Side-clamp (C) | General | ○ |

| Hub Split | △ | |

| With Keyway | ○ | |

| Shaft-insertion (I) | △ | |

| Taper-ring (T) | General | △ |

| For High-Precision, High-Speed Spindles |

△ | |

※ △ symbol in the above table means that the availability is subject to differ according to each outer diameter size.

※ You may check more details on the “Dimensions / Performance” tables in the following pages.

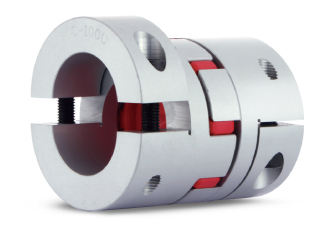

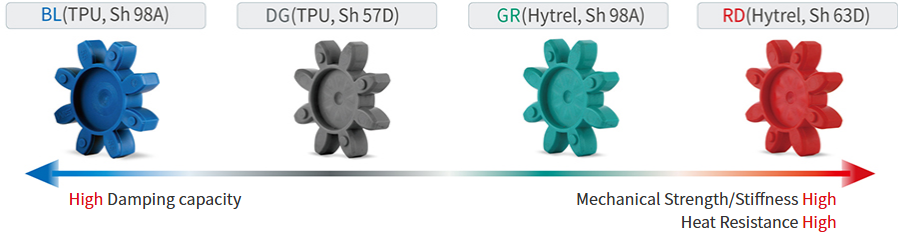

Sleeve Material

- A Sleeve (Spider) is the medium that transmits motion absorbing impact and misalignment and it is the core part of Jaw couplings.

- Hytrel® is superior in terms of mechanical strength, abrasion resistance and heat resistance whereas TPU (Thermoplastic polyurethane) has higher damping capacity.

- According to material and shore hardness, there are 3 types of sleeves, RD(Hytrel, Sh 63D), GR(Hytrel, Sh 98A), DG(TPU, Sh 57D), and BL(TPU, Sh 98A) respectively.

Sleeve Types (General: Center-Solid / TH: Center-Through)

If the shaft has to be inserted deeper than L1 value, we can provide appropriate center-through sleeves. Please refer to “HOW TO ORDER” in the previous page. Either type has the identical value of transmittable torque and the same level of misalignment absorption. Due to the structural characteristics of the center-through (TH) type spacer, slight variations in static torsional stiffness values may occur.

| Type | General : Center-Solid | TH : Center-Through | ||||||

|---|---|---|---|---|---|---|---|---|

| 14-30 | – |  |

|

|

– |  |

|

|

| DG | BL | RD | GR | DG | BL | RD | GR | |

| 40 | – |  |

|

|

– |  |

|

|

| DG | BL | RD | GR | DG | BL | RD | GR | |

| 48 | – |  |

|

|

– |  |

|

|

| DG | BL | RD | GR | DG | BL | RD | GR | |

| 55-100 |  |

|

|

|

|

|

|

|

| DG | BL | RD | GR | DG | BL | RD | GR | |

| 120-135 | – | – | – |  |

|

|||

| DG | BL | RD | GR | DG | BL | RD | GR | |

| 160 | – | – | – |  |

|

|||

| DG | BL | RD | GR | DG | BL | RD | GR | |

Center-Through Sleeve Bore Size

| Model | Max. standard ID | Sleeve-TH ID |

|---|---|---|

| SJC-14 | Ø5 | – |

| SJC-20 | Ø8 | Ø6 |

| SJC-25 | Ø10 | Ø6.35 |

| SJC-30 | Ø14 | Ø8 |

| SJC-40 | Ø18 | Ø15 |

| SJC-48 | Ø28 | Ø20 |

| SJC-55 | Ø28 | Ø25 |

| SJC-65 | Ø35 | Ø25 |

| SJC-80 | Ø45 | Ø32 |

| SJC-90 | Ø50 | Ø40 |

| SJC-100 | Ø60 | Ø45 |

| SJC-120 | Ø65 | Ø55 |

| SJC-135 | Ø70 | Ø65 |

| SJC-160 | Ø80 | Ø75 |

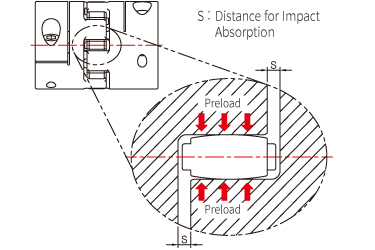

Preload on Sleeves

Sung-il’s SJC Series is assembled with adequate preload and its outstanding features are as below.

1. Improved static torsional stiffness brings faster response

2. Minimized backlash as there is no clearance at the assembled area

| Model | Distance S | Model | Distance S | Model | Distance S |

|---|---|---|---|---|---|

| SJC-14 | 1.0mm | SJC-40 SJC-48 SJC-55 |

2mm | SJC-100 | 3.5mm |

| SJC-20 | 1.0mm | SJC-65 | 2.5mm | SJC-120 | 4mm |

| SJC-25 | 1.2mm | SJC-80 | 3mm | SJC-135 | 4.5mm |

| SJC-30 | 1.5mm | SJC-90 | 3mm | SJC-160 | 5mm |

Performance table according to sleeve types

| Model | Code | Material | Shore Hardness |

Rated Torque (N·m) |

Max. Torque (N·m) |

Static Torsional Stiffness (N·m/rad) |

Permissible Misalignment | ||

|---|---|---|---|---|---|---|---|---|---|

| Angular (˚) |

Parallel (mm) |

End-play (mm) |

|||||||

| SJC-14 | BL | TPU | 98A | 2 | 4 | 22 | 1 | 0.05 | -0.2 ~ +0.6 |

| GR | Hytrel | 98A | 2 | 4 | 25 | 1 | 0.05 | -0.2 ~ +0.6 | |

| RD | Hytrel | 63D | 2.5 | 5 | 34 | 1 | 0.03 | -0.2 ~ +0.6 | |

| SJC-20 | BL | TPU | 98A | 4 | 8 | 50 | 1 | 0.07 | -0.3 ~ +0.8 |

| GR | Hytrel | 98A | 4 | 8 | 60 | 1 | 0.07 | -0.3 ~ +0.8 | |

| RD | Hytrel | 63D | 6 | 12 | 74 | 1 | 0.05 | -0.3 ~ +0.8 | |

| SJC-25 | BL | TPU | 98A | 9 | 18 | 220 | 1 | 0.07 | -0.4 ~ +1.0 |

| GR | Hytrel | 98A | 9 | 18 | 260 | 1 | 0.07 | -0.4 ~ +1.0 | |

| RD | Hytrel | 63D | 12 | 24 | 300 | 1 | 0.05 | -0.4 ~ +1.0 | |

| SJC-30 | BL | TPU | 98A | 12 | 24 | 170 | 1 | 0.08 | -0.5 ~ +1.0 |

| GR | Hytrel | 98A | 12 | 24 | 200 | 1 | 0.08 | -0.5 ~ +1.0 | |

| RD | Hytrel | 63D | 16 | 32 | 220 | 1 | 0.06 | -0.5 ~ +1.0 | |

| SJC-40 | BL | TPU | 98A | 17 | 34 | 1,500 | 1 | 0.06 | -0.6 ~ +1.2 |

| GR | Hytrel | 98A | 17 | 34 | 1,600 | 1 | 0.06 | -0.6 ~ +1.2 | |

| RD | Hytrel | 63D | 21 | 42 | 1,750 | 1 | 0.04 | -0.6 ~ +1.2 | |

| SJC-48 | BL | TPU | 98A | 35 | 70 | 1,800 | 1 | 0.08 | -0.6 ~ +1.3 |

| GR | Hytrel | 98A | 35 | 70 | 2,800 | 1 | 0.08 | -0.6 ~ +1.3 | |

| RD | Hytrel | 63D | 40 | 80 | 3,600 | 1 | 0.05 | -0.6 ~ +1.3 | |

| SJC-55 | BL | TPU | 98A | 60 | 120 | 3,000 | 1 | 0.09 | -0.6 ~ +1.4 |

| DG | TPU | 57D | 60 | 120 | 4,500 | 1 | 0.08 | -0.6 ~ +1.4 | |

| GR | Hytrel | 98A | 60 | 120 | 4,500 | 1 | 0.09 | -0.6 ~ +1.4 | |

| RD | Hytrel | 63D | 75 | 150 | 6,000 | 1 | 0.06 | -0.6 ~ +1.4 | |

| SJC-65 | BL | TPU | 98A | 150 | 300 | 6,500 | 1 | 0.1 | -0.6 ~ +1.5 |

| DG | TPU | 57D | 150 | 300 | 8,500 | 1 | 0.09 | -0.6 ~ +1.5 | |

| GR | Hytrel | 98A | 150 | 300 | 8,500 | 1 | 0.1 | -0.6 ~ +1.5 | |

| RD | Hytrel | 63D | 180 | 360 | 10,000 | 1 | 0.08 | -0.6 ~ +1.5 | |

| SJC-80 | BL | TPU | 98A | 300 | 600 | 8,000 | 1 | 0.1 | -0.6 ~ +1.5 |

| DG | TPU | 57D | 300 | 600 | 12,000 | 1 | 0.09 | -0.6 ~ +1.5 | |

| GR | Hytrel | 98A | 300 | 600 | 12,000 | 1 | 0.1 | -0.6 ~ +1.5 | |

| RD | Hytrel | 63D | 380 | 760 | 14,000 | 1 | 0.08 | -0.6 ~ +1.5 | |

| SJC-90 | BL | TPU | 98A | 450 | 900 | 12,000 | 1 | 0.15 | -0.6 ~ +2.0 |

| DG | TPU | 57D | 450 | 900 | 14,000 | 1 | 0.12 | -0.6 ~ +2.0 | |

| GR | Hytrel | 98A | 450 | 900 | 14,000 | 1 | 0.15 | -0.6 ~ +2.0 | |

| RD | Hytrel | 63D | 500 | 1,000 | 16,000 | 1 | 0.1 | -0.6 ~ +2.0 | |

| SJC-100 | BL | TPU | 98A | 500 | 1,000 | 24,000 | 1 | 0.15 | -0.6 ~ +2.0 |

| DG | TPU | 57D | 500 | 1,000 | 24,000 | 1 | 0.12 | -0.6 ~ +2.0 | |

| GR | Hytrel | 98A | 500 | 1,000 | 30,000 | 1 | 0.15 | -0.6 ~ +2.0 | |

| RD | Hytrel | 63D | 600 | 1,200 | 40,000 | 1 | 0.1 | -0.6 ~ +2.0 | |

| SJC-120 | GR | Hytrel | 98A | 620 | 1,240 | 50,000 | 0.9 | 0.16 | -1.0 ~ +2.2 |

| RD | Hytrel | 63D | 740 | 1,480 | 90,000 | 0.8 | 0.11 | -1.0 ~ +2.2 | |

| SJC-135 | GR | Hytrel | 98A | 850 | 1,700 | 60,000 | 0.9 | 0.17 | -1.0 ~ +2.2 |

| RD | Hytrel | 63D | 1,050 | 2,100 | 100,000 | 0.8 | 0.12 | -1.0 ~ +2.2 | |

| SJC-160 | GR | Hytrel | 98A | 1,700 | 3,400 | 90,000 | 0.9 | 0.2 | -1.5 ~ +3.0 |

| RD | Hytrel | 63D | 2,100 | 4,200 | 150,000 | 0.8 | 0.14 | -1.5 ~ +3.0 | |