Shaft Coupling

Coupling is a core component that transmits power and motion

from the driving shaft to the driven part while absorbing misalignment

and any possible factors that could reduce efficiency of machines

(e.g. vibration, noise, electric current, etc.)

SJC Series (SJCP-T) Go to SJC Series(Index)

Jaw Coupling (For High-Precision, High-Speed Spindles)

- Product Overview

-

Dimensions / Performance / CAD

Taper-ring (For High-Precision, High-Speed Spindles)

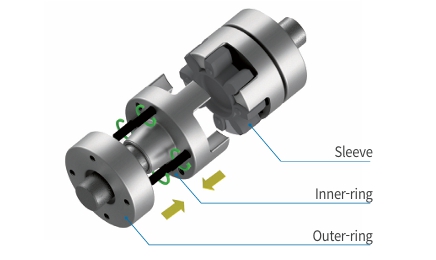

Structure and Features

- Optimized for spindle drive systems requiring high precision and high speed

- Excellent centering accuracy and precise concentricity maintained through the combination of precision-machined hub and sleeve

- The tapered hub design, combined with inner and outer rings, provides simple yet strong fastening through bolt tightening

Feature 1 Optimized for high-Precision / high-Speed rotation

- Ensures highly accurate shaft fastening by applying IT6 tolerance to the bore

- Minimizes rotational vibration through strict control of inner and outer diameter run-out

- Enhances balance performance through structural symmetry and high precision

Feature 2 Reliability / Assembly Efficiency

- Designed with consideration of appropriate axial assembly force, enabling easy installation and maintenance

- Improves backlash control and drive accuracy through optimized preload

- Ensures high reliability with excellent heat resistance, fatigue strength, and impact resistance

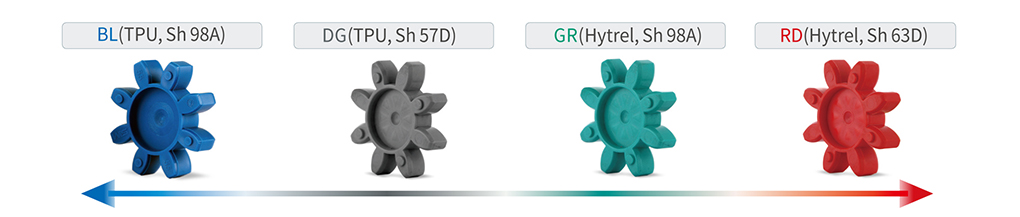

Feature 3 Various Sleeve Options

High Damping capacity

Mechanical Strength/Stiffness High

Heat Resistance High

- A Sleeve (Spider) is the medium that transmits motion absorbing impact and misalignment and it is the core part of Jaw couplings.

- Hytrel® is superior in terms of mechanical strength, abrasion resistance and heat resistance whereas TPU (Thermoplastic polyurethane) has higher damping capacity.

- According to material and shore hardness, there are 3 types of sleeves, RD(Hytrel, Sh 63D), GR(Hytrel, Sh 98A), DG(TPU, Sh 57D), and BL(TPU, Sh 98A) respectively.

※ Made-to-Order (Customization) Support

- Connection method and fit tolerance can be customized.

- Balancing tab machining is available for high-speed rotation.

- Material, geometry, surface treatment, and other specifications can be customized.

Taper-ring (For High-Precision, High-Speed Spindles)

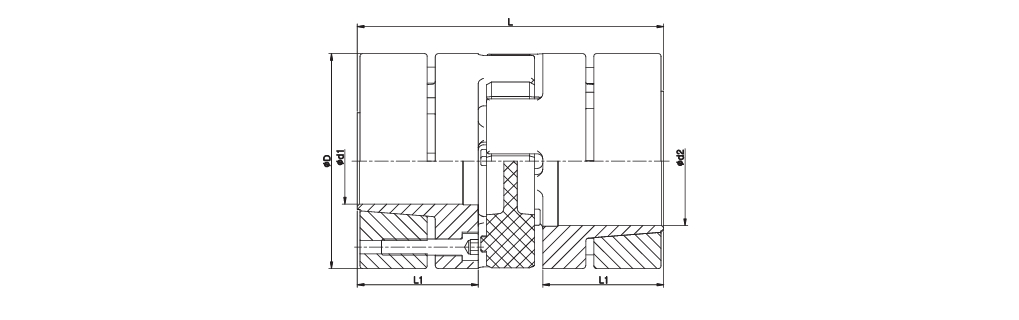

Dimensions / Performance

| Model | Size (±0.3mm) | d1, d2 (mm) | Screws | Rated Torque (N·m) |

Max. Torque (N·m) |

Moment of Inertia (kg·m2) |

Static Torsional Stiffness (N·m/rad) |

Mass (g) |

Permissible Misalignment | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | L | L1 | Min. | Max. | Size | The no. of Screws |

Fastening Torque (N·m) |

Angular (˚) |

Parallel (mm) |

End-play (mm) |

||||||

| SJCP-55T-BL-TH | 55 | 78 | 30 | 14 | 28 | M5 | 4 | 8 | 60 | 120 | 4.11×104 | 3,000 | 850 | 1 | 0.09 | -0.5 ~ +1.4 |

| SJCP-55T-DG-TH | 55 | 78 | 30 | 14 | 28 | M5 | 4 | 8 | 60 | 120 | 4.11×104 | 4,500 | 850 | 1 | 0.08 | -0.5 ~ +1.4 |

| SJCP-55T-GR-TH | 55 | 78 | 30 | 14 | 28 | M5 | 4 | 8 | 60 | 120 | 4.11×104 | 4,500 | 850 | 1 | 0.09 | -0.5 ~ +1.4 |

| SJCP-55T-RD-TH | 55 | 78 | 30 | 14 | 28 | M5 | 4 | 8 | 75 | 150 | 4.11×104 | 6,000 | 850 | 1 | 0.06 | -0.5 ~ +1.4 |

| SJCP-65T-BL-TH | 65 | 90 | 35 | 15 | 38 | M5 | 8 | 8 | 150 | 300 | 8.76×104 | 6,500 | 1,240 | 1 | 0.1 | -0.6 ~ +1.5 |

| SJCP-65T-DG-TH | 65 | 90 | 35 | 15 | 38 | M5 | 8 | 8 | 150 | 300 | 8.76×104 | 8,500 | 1,240 | 1 | 0.09 | -0.6 ~ +1.5 |

| SJCP-65T-GR-TH | 65 | 90 | 35 | 15 | 38 | M5 | 8 | 8 | 150 | 300 | 8.76×104 | 8,500 | 1,240 | 1 | 0.1 | -0.6 ~ +1.5 |

| SJCP-65T-RD-TH | 65 | 90 | 35 | 15 | 38 | M5 | 8 | 8 | 180 | 360 | 8.76×104 | 10,000 | 1,240 | 1 | 0.08 | -0.6 ~ +1.5 |

| SJCP-80T-BL-TH | 80 | 114 | 45 | 20 | 45 | M6 | 8 | 13 | 300 | 600 | 2.58×103 | 8,000 | 2,380 | 1 | 0.1 | -0.6 ~ +1.5 |

| SJCP-80T-DG-TH | 80 | 114 | 45 | 20 | 45 | M6 | 8 | 13 | 300 | 600 | 2.58×103 | 12,000 | 2,380 | 1 | 0.09 | -0.6 ~ +1.5 |

| SJCP-80T-GR-TH | 80 | 114 | 45 | 20 | 45 | M6 | 8 | 13 | 300 | 600 | 2.58×103 | 12,000 | 2,380 | 1 | 0.1 | -0.6 ~ +1.5 |

| SJCP-80T-RD-TH | 80 | 114 | 45 | 20 | 45 | M6 | 8 | 13 | 380 | 760 | 2.58×103 | 14,000 | 2,380 | 1 | 0.08 | -0.6 ~ +1.5 |

| SJCP-90T-BL-TH | 95 | 126 | 50 | 25 | 50 | M8 | 4 | 30 | 450 | 900 | 5.93×103 | 12,000 | 4,090 | 1 | 0.15 | -0.6 ~ +2.0 |

| SJCP-90T-DG-TH | 95 | 126 | 50 | 25 | 50 | M8 | 4 | 30 | 450 | 900 | 5.93×103 | 14,000 | 4,090 | 1 | 0.12 | -0.6 ~ +2.0 |

| SJCP-90T-GR-TH | 95 | 126 | 50 | 25 | 50 | M8 | 4 | 30 | 450 | 900 | 5.93×103 | 14,000 | 4,090 | 1 | 0.15 | -0.6 ~ +2.0 |

| SJCP-90T-RD-TH | 95 | 126 | 50 | 25 | 50 | M8 | 4 | 30 | 500 | 1,000 | 5.93×103 | 16,000 | 4,090 | 1 | 0.1 | -0.6 ~ +2.0 |

| SJCP-100T-BL-TH | 104 | 140 | 56 | 30 | 55 | M10 | 4 | 50 | 500 | 1,000 | 9.68×103 | 24,000 | 5,540 | 1 | 0.15 | -0.6 ~ +2.0 |

| SJCP-100T-DG-TH | 104 | 140 | 56 | 30 | 55 | M10 | 4 | 50 | 500 | 1,000 | 9.68×103 | 24,000 | 5,540 | 1 | 0.12 | -0.6 ~ +2.0 |

| SJCP-100T-GR-TH | 104 | 140 | 56 | 30 | 55 | M10 | 4 | 50 | 500 | 1,000 | 9.68×103 | 30,000 | 5,540 | 1 | 0.15 | -0.6 ~ +2.0 |

| SJCP-100T-RD-TH | 104 | 140 | 56 | 30 | 55 | M10 | 4 | 50 | 600 | 1,200 | 9.68×103 | 40,000 | 5,540 | 1 | 0.1 | -0.6 ~ +2.0 |

※ The SJCP series is supplied on a made-to-order basis, and the above specification table is for reference only.

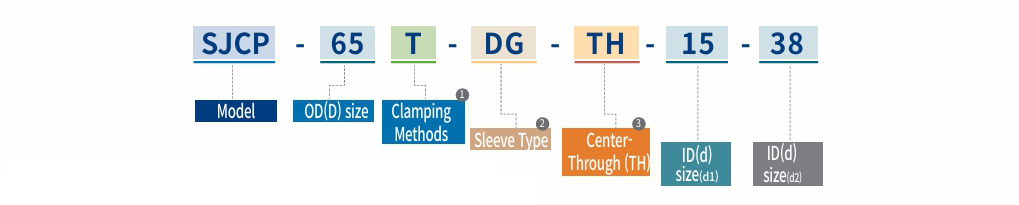

How to Order – Taper-ring (For high-Precision, high-Speed Spindles)

① Clamping Methods

- T

- Taper-ring

② Sleeve Type (Shore Hardness)

- RD

- Hytrel, Sh63D

- GR

- Hytrel, Sh98A

- DG

- TPU, Sh57D

- BL

- TPU, Sh98A

③ Center-Through

- No mark

- Center-Solid

- TH

- Center-Through