Shaft Coupling

Coupling is a core component that transmits power and motion

from the driving shaft to the driven part while absorbing misalignment

and any possible factors that could reduce efficiency of machines

(e.g. vibration, noise, electric current, etc.)

SJC Series Go to SJC Series(Index)

Jaw Coupling

- Product Overview

-

Dimensions / Performance / CAD

Shaft-insertion

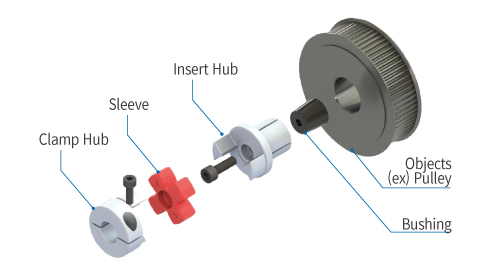

Features of SJC-I Series

- Easy attachment to various hub types e.g. Pulleys, Gears, Sprockets, or Hollow shafts

- Space-saving design

- Simple clamping methods by tightening a single bolt

- Self-centering function by the taper structure

- Various types of coupling hubs (e.g. Side-clamp, Set-screw) can be combined

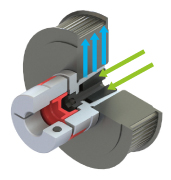

Principles

- Bushing and Insert hub are tightly coupled by the thrust of fastening screws.

- And then the insert part gets spread outward due to the taper structure and clamped into the inner diameter on the other side.

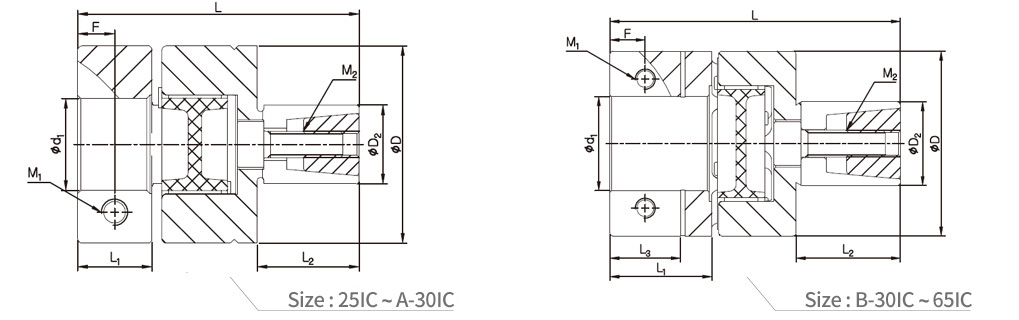

Dimensions

| Model | Coupling hub OD | Shaft-insertion hub OD |

|---|---|---|

| SJC-25I□ | 25mm | 10mm |

| SJC□-30I□ | 30mm | 12mm |

| SJC□-40I□ | 40mm | 20mm |

| SJC-55I□ | 55mm | 25mm |

| SJC-65I□ | 65mm | 35mm |

※ OD: Outer Diameter

※ Please contact Sung-il Customer Service team for non-standard Inserted hub OD products.

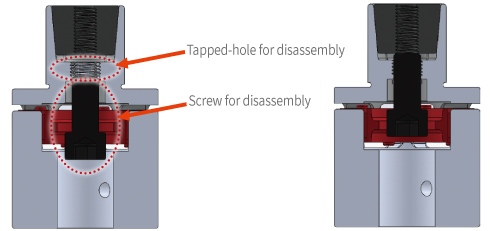

How to Disassemble

① Please refer to the below table.

| Model | Fastening screw | Screw for disassembly |

|---|---|---|

| SJC-25I | M3 | M4 |

| SJC-30I | M4 | M5 |

| SJC-40I | M6 | M8 |

| SJC-55I | M8 | M10 |

| SJC-65I | M10 | M12 |

② After removing fastening screws, insert a screw for disassembly and fasten it into the tapped-hole for disassembly. And then, bushing comes out being disassembled by thrust of the screw.

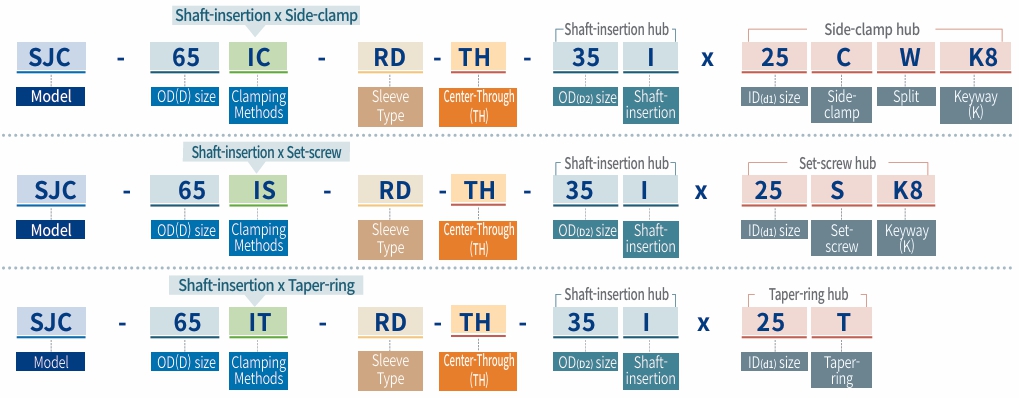

How to Order

※ The standard spacer for the SJC-I series is a center-through (TH) type.

Shaft-insertion x Side-clamp

Dimensions / Performance

- The Moment of Inertia and Mass values are based on products with max. Inner diameter.

- Please modify rated/max. torque value with temperature correction factor when it’s higher than 30°C.

- It’s not allowed to have other complementary options to enhance clamping force such as keyway etc. on the shaft-insertion hub.

- Please contact Sung-il Customer Service team for non-standard Inserted hub OD(D2) products.

- Please refer to previous pages for the standard ID range of Side-clamp hubs.

- It’s also possible to assemble with space-saving side-clamp, set-screw and taper-ring hubs.